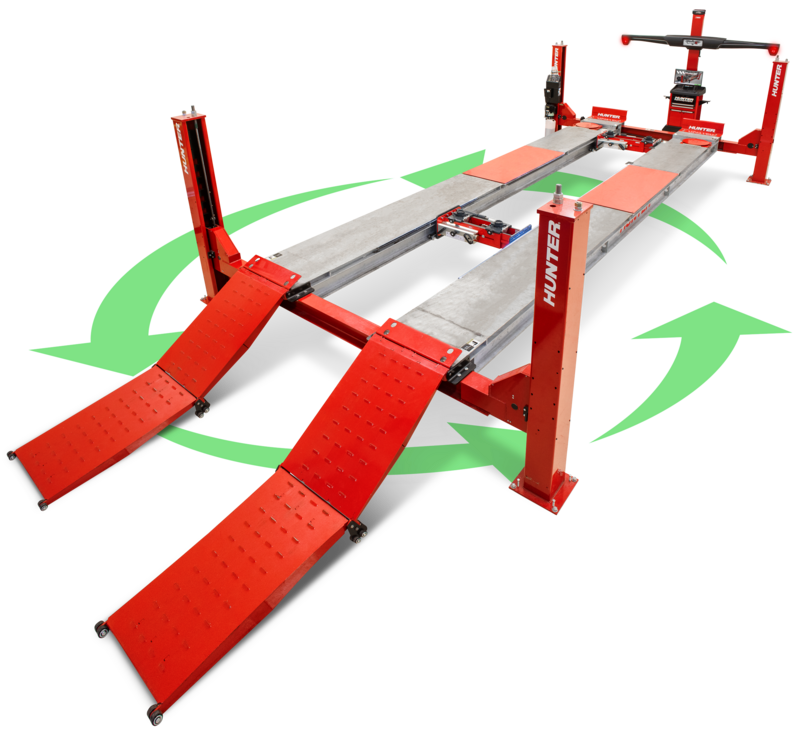

Move the aligner for use in any bay, on the floor or a lift, with adjustable camera beam.

Alignment System

Hunter HawkEye® XL

Fast and highly-capable alignment machine featuring Hunter's patented camera technology designed for heavy-duty semi truck and bus, medium-duty utility and fleet, and light-duty passenger vehicles.

HawkEye® XL

/

HawkEye® XL features

Three-dimensional XL targets are durable, low maintenance, and non-electronic

High-definition cameras are accurate, precise, and offer extra-long-range sight

Capture all measurements in a single rolling compensation

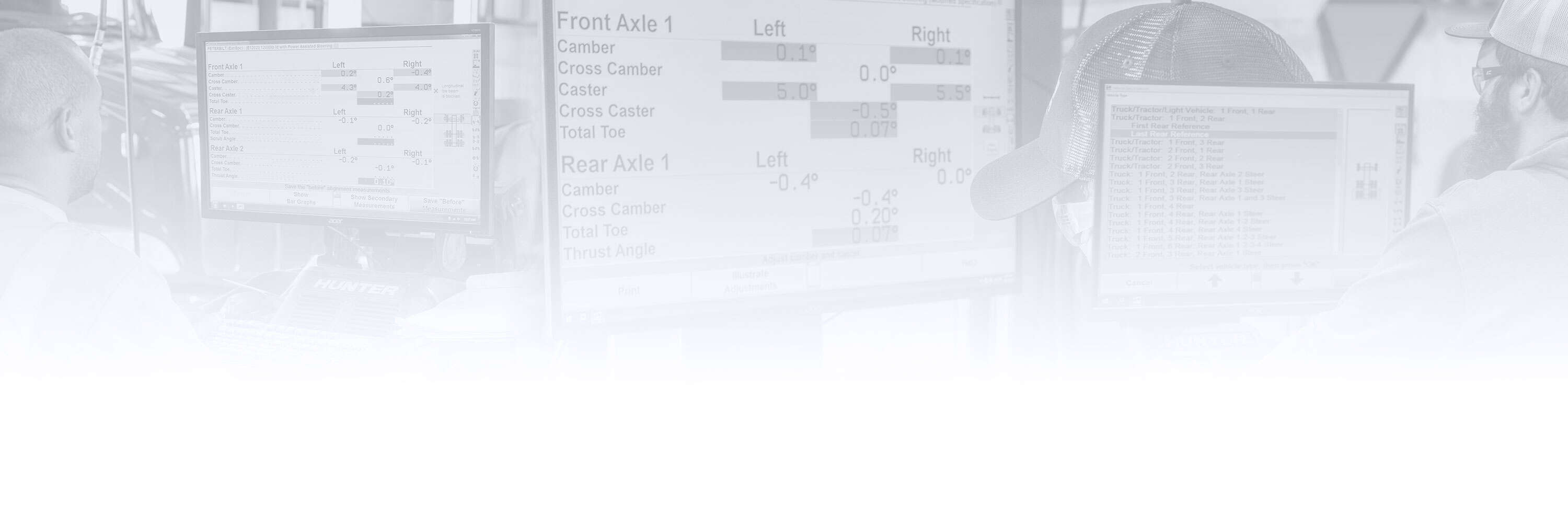

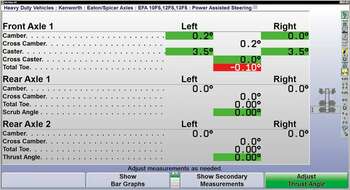

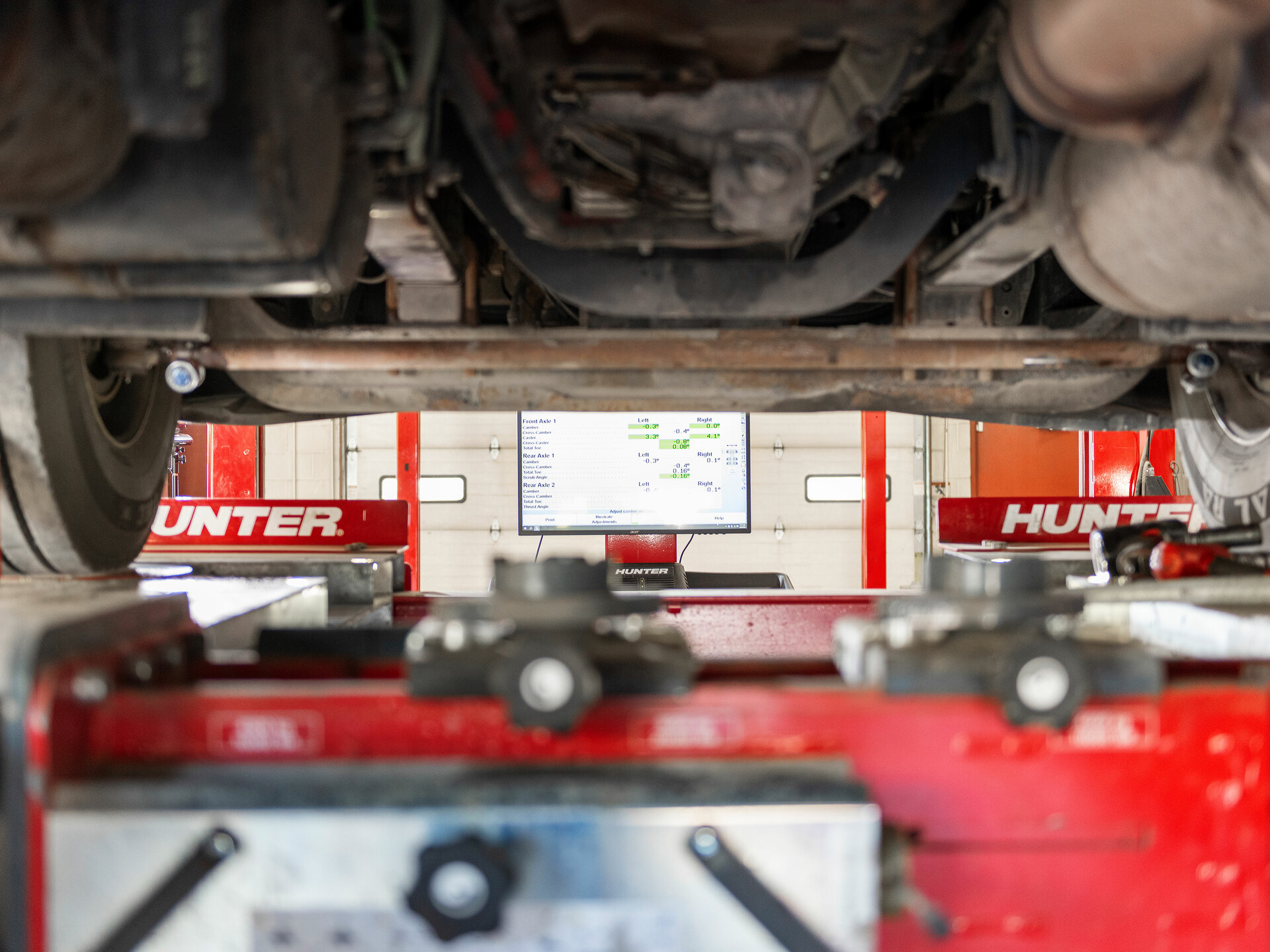

See live alignment readings from three axles at once

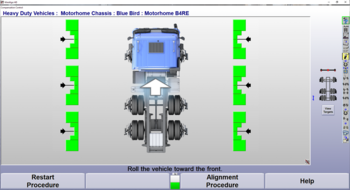

Perform wheel alignments on any surface, in any bay

Fully Integrated Alignment rack integration streamlines processes

HunterNet® 2 connectivity to see and manage your performance

Hunter's industry-standard vision technology built for commercial vehicles

Alignments in any bay

Multi-Axle Readings

See live alignment readings from three axles at one time with guided procedures.

XL Targets

Hunter's patented 3D targets offer extreme durability, low maintenance, and no electronics at the wheel.

High-definition cameras

Extra-long range, high-resolution cameras precisely monitor each wheel in a 3D space to provide pinpoint-accurate measurements.

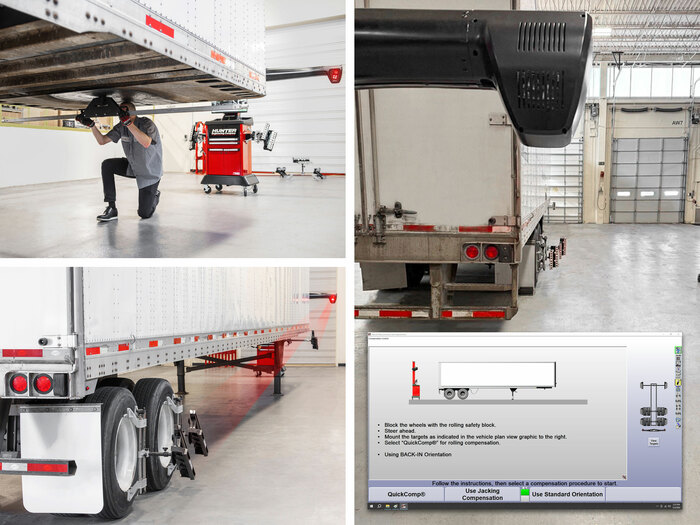

Trailer alignment

Long-range cameras easily see targets on 53-foot trailers. Align using optional kingpin adaptor.

Truck Pusher

Optional

Effortlessly move vehicle for rolling comp with rechargeable battery-powered pusher.

New at SEMA 2025: HawkEye® XL Updates

See the latest enhancements introduced at SEMA.

HawkEye® XL helps Prime Inc. maintain its “nonstop” pace

The new HawkEye® XL commercial aligner was designed for shops like Prime Inc. in mind.

HawkEye® XL Aligner Passenger QuickGrip® Adaptor Demonstration

HawkEye XL® Alignment System: Beginner's Operation Guide

Field training manager Miles Dierker describes the proper techniques for the smoothest and most efficient operation of the Hawkeye XL®, powered by WinAlign® software.

Fast and highly-capable HawkEye® XL heavy-duty alignment machine

The all-new HawkEye® XL alignment system from Hunter Engineering® features three-dimensional XL targets, high-definition cameras, and three-axle live alignment readings from a single rolling compensation on any surface or any bay.

Designed & Built in the USA

For 75 years, Hunter Engineering Company® has been designing and building automotive service equipment in the USA.

Big or small, align them all with HawkEye® XL

Hunter Engineering’s new Hawkeye® XL aligner handles everything from Class 8 trucks down to passenger vehicles.

Ready for whatever comes through your door

Align a wide range of commercial vehicles from semi-truck tractors, trailers, big rigs, buses, box trucks, and even passenger vehicles.

XL targets for XL alignments

Always ready

No batteries, cables or wireless signal connection are required.

Wheel adaptor options

Highly-versatile self-centering wheel adaptors come standard with optional magnetic adaptors to simplify attachment.

Low cost of ownership

Extremely durable and low-maintenance design make Hunter targets a shop favorite..

Calculate your payoff and profits

Trailers carry the load. Give them the alignment they deserve.

Long-range cameras easily see targets on 53 foot trailers.

Align using optional kingpin adaptor.

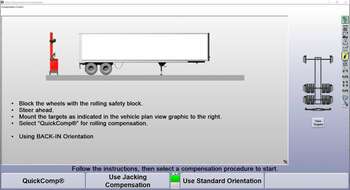

NEW back-in trailer alignment ability via latest Hunter software.

Save yourself the trip

Convenient storage available to hang targets and store truck pusher for quick access.

Secondary console provides better visibility and control. Mounts to cart shown.

All-day power from your own connected battery pack lets you go fully cordless.

Complete axle configurations

Select from 50 unique procedures or build your own truck and trailer axle configurations to perform the fastest, easiest, step-by-step alignment process on virtually any vehicle.

Back-in trailer procedure

Align backed-in trailers with or without the truck connected.

Three Axles Live

See three axles live with all measurements at once. Reduce setup time through minimal target movement.

ExpressAlign®

Perform every alignment with a streamlined procedure. ExpressAlign® analyzes each job and presents the optimal action sequence with the minimum steps required.

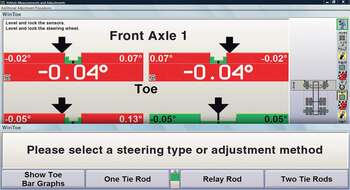

WinToe®

Ensure a straight steering wheel every time without repeated adjustments or using a steering wheel holder. Works with all vehicles on the road today, from cars to Freightliners.

Rear Axle Adjustment

Cut adjustment times in half for rear axle corrections. Graphics let you get it right on the first try. (Patented)

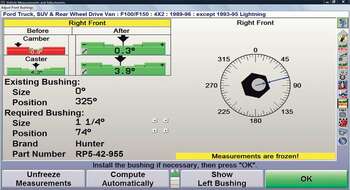

Automatic Bushing Calculator®

Calculate the proper bushing size and position adjustment without wasting time with a zero bushing. Eases the process of servicing Ford F-150-450's.

Patented

Adjustment Videos

Strengthen technician competency and extend profit opportunities with helpful adjustment videos.

The unsurpassed industry standard software

Step-by-step, vehicle-specific procedures combined with patented power tools ensure precise, first-time alignment on any vehicle from Class 8 trucks to passenger cars.

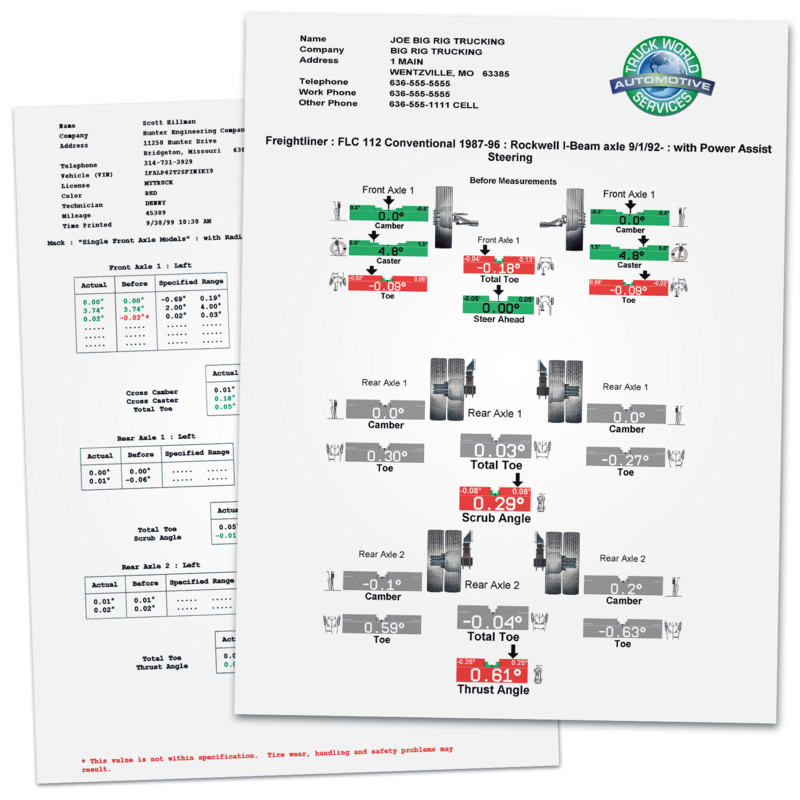

WinAlign® HD printouts provide a comprehensive outlook of the multi-axle vehicle's wheel alignment measurements.

Use the optional cordless Remote Indicator to see live adjustments from underneath the truck.

Take less trips around the truck.

Streamline the alignment process with Fully Integrated Alignment (FIA).

Requires FIA-capable Hunter lift or turnplates

1 trip

To the aligner console

0 jacking axles

Required

81 steps

Total in the process

4 minutes

To get alignment readings

WinAlign® console

Communicates directly with lift to automatically operate turnplates and slip plates.

Lift console

Raising the vehicle triggers the sensors to look for wheel targets.

PowerSlide® system

Slip plates and turnplates automatically lock and unlock at the appropriate times.

Hunter's Heavy-Duty Four-Post semi and truck lift features galvanized runways, turn plate pockets, and slip plates for servicing heavy or standard vehicles. Optional FIA functions connect it to the aligner to streamline the process.

Turn plate options for floor or other racks

Choose the configuration that fits your shop

Cabinet-mounted

Use the aligner in multiple bays with a full range of travel for additional lift height.

Fixed column

Suitable for traditional HD pits and challenging or tight bay setups. Moveable console can be placed where needed for easy technician access.

Expand your service capabilities with these options

Mini Self-Centering Clamps

Mount to hub center of front rims. (set of 2)

Medium-Duty spacer kit

This kit contains 4 spacers for medium-duty trucks.

QuickGrip® adaptors

The industry's fastest and safest target adaptors offer no metal-to-metal contact for two-axle vehicles.

Live Ride Height Targets

Calculate and view live ride height for select passenger vehicles.

Scan every vehicle, find every opportunity.

Quick Check® Commercial inspects for camber, total toe, scrub and tyre wear on every truck, axle and tyre that comes into your shop with no technician required. Keep your equipment producing with a steady stream of high-margin alignments.

Want to see it in action?

Send a message to your local Hunter heavy-duty business consultant to schedule a free on-site demo.

HunterNet® Portal

Connect your equipment to your business to maximize your shop's performance, simplify customer discussions with selling tools, and view extensive undercar information.

Recall alignment results

View previously serviced vehicles and recall printouts.

Monitor trends

Get a high-level overview of your alignment machine usage trends.

View usage details

See in-depth alignment machine usage statistics.

Receive daily reports

Setup to receive daily Push Reports to keep your goals and performance in check.

Gallery

Because of continuing technological advances, features and configurations shown in customer photos may vary.

Documents

-

Brochures

-

Specification Sheets

-

Accessories

-

Printouts

-

Operations Manuals

Receive same- or next-day service

Get a free quote or on-site demo

Register for ASE-accredited training

General information & questions

This contact form is intended for legitimate Hunter equipment and service inquiries. All other use is prohibited and will be discarded. See Full Terms of Use

Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.

From raw steel to finished product. When you choose Hunter, you're investing in more than 1,000 American workers.