Hunter uses state-of-the-art fiber optic lasers and plasma cutters to turn sheet and plate steel into precision cut parts

Designed and Built in the USA

From raw steel to finished product. When you choose Hunter, you’re investing in more than 1,000 American workers.

Locations

St. Louis, MO

Headquarters & R&D

Products

- Alignment Sensors

- Balance Collets

- Inspection Sensors

- Research & Testing

Durant, MS

Fabrication & Assembly

Products

- Alignment Racks

- Swing Jacks

- Driver Over Tread Depth

- On-Car Brake Lathes

- Bench Lathes

Raymond, MS

Electronics Manufacturing

Products

- Circuit Boards

- Cables & Wire Harnesses

- Electronic Subassesmblies

Raymond, MS

Fabrication & Assembly

Products

- Alignment Systems

- Wheel Balancers

- Revolution™ Tire Changers

Beginning in 1946 with World War II veteran and founder Lee Hunter, Jr., and continuing through today with Vietnam War veteran and chairman Stephen F. Brauer, Hunter Engineering has been veteran-owned for its entire history and is among the largest veteran-owned businesses in St. Louis, MO.

Processes

Laser & Plasma Cutting

Fabrication & Welding

Hunter’s team of certified welders along with a fleet of welding robots ensure industry-leading precision and quality go into each part.

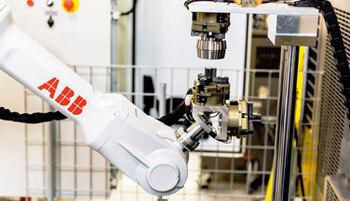

CNC Cutting

Skilled machine operators use CNC milling machines and cutting-edge robotic systems to manufacture high-precision components.

Powder Coating

Hunter products undergo a cleaning and phosphate process followed by high performance powder-coating for world-class appearance, durability and corrosion resistance.

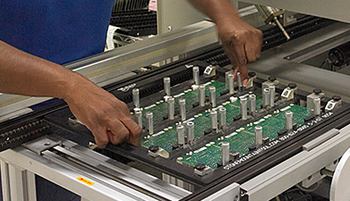

Circuit Boards

To ensure quality and reliability, Hunter designs and builds circuit boards in-house with state-of-the-art equipment. Hunter produces over one million boards and cable assemblies every year.

Assembly & Testing

Hunter assemblers and inspectors undergo months of training and testing to become certified. Each part undergoes multiple levels of inspection to ensure it's right before it leaves our plant.